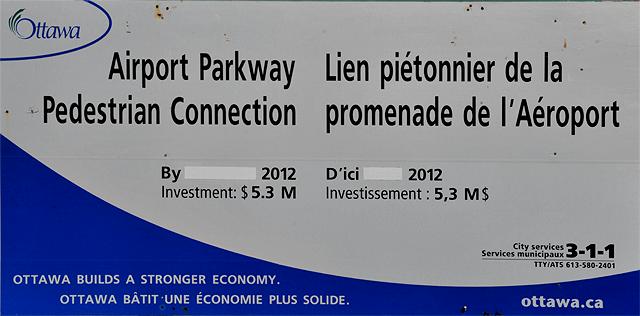

2012 construction

6 January:

Ottawa Sun:

Big trouble

on Airport Pkwy. pedestrian bridge?

18 March:

Ottawa Sun:

$5 million footbridge

delayed

22 March:

Ottawa Business Journal: Concrete woes halt footbridge construction on parkway

12 April:

the completion date has been blanked off and the million dollar decision made that the tower

can't be repaired, it will have to be demolished and rebuilt. The delay costs will be borne by the

Hunt Club community. The dollar cost seems to be borne by Bray at least for now; the city will be

charging liquidated damages (penalty for late completion) starting 15 May. Negotiations with the

concrete supplier Tomlinson concerning responsibility have ended for now with Bray choosing another

supplier for concrete, Lafarge. The city project manager

is now Luke Foley P.Eng.; the city closes down all communications with residents concerning the

project and orders contractors and subcontractors to do the same.

Everything that follows in this account is my personal best estimates based upon what I could see from outside the construction fencing, supplemented on occasion by informal chats through the fencing, and upon public releases of information. Many of those public releases are due to the diligence of reporters for the Ottawa Sun and Ottawa Citizen and their financial support for Freedom of Information requests.

Ottawa Sun:

Crumbling bridge

needs to come down

CBC: Airport Parkway bridge to be demolished and rebuilt

Ottawa Citizen: "Concrete problems mean city will tear down Airport

Parkway bridge tower and start over"

19 April:

News EMC: Troubled bridge to be demolished

2 May:

demolition of the tower begins as the engineers commiserate with each other in the foreground.

A green fabric shield protects cars using the parkway from dust and flying debris

Bray issues a public letter; the independent engineering company is A.Dagenais & Assoc. Inc.

work begins to assemble the concrete wall guarding the west approach pillars

6 May:

demolition of the tower pauses; the remaining concrete will be saw cut along the line then the

top lifted off to preserve the rebar that bonds the tower to the support pier. If this were not

done, the pier would have to be largely demolished and replaced as well

14 May:

saw cut completed, the last stage of tower removal is done by hand to minimize damage to the rebar. In 2013 this effort is judged inadequate; additional tying of tower to pier will be required

the approaches to the bridge are being built with light weight expanded polystyrene rather than

rock fill. The underlying soil is weak marine silty clay; heavy rock fill would keep settling

unpredictably for years. The blocks, about 2% the density of rock fill, will be staggered to

distribute the light load over local soil weaknesses more than is possible with rock fill

24 May:

News EMC: Footbridge a priority: councillor

26 May:

the rebar to join the new tower to the pier is exposed ready for straightening and recoating

(although no recoating is ever observed), the dust shield is removed, and forms for the tower are

being returned to the site. The exceptionally thin deck cross section of the Genivar design is

visible in the east approach span in the background; it is later found to be too thin and requires

reinforcing to maintain structural integrity

31 May:

the contractual date for 100% completion of the project

3 June:

tower formwork rises again, hopefully for the last time

the polystyrene core of the west approach is now covered with a waterproof membrane and earth

16 June:

work is proceeding very slowly; the stainless steel rebar has been delivered and installed,

along with some of the foam formwork

16 July:

after three weeks in which nothing has been done, work has restarted; questions from the public

are not acknowledged by the city, Bray or Genivar

rebar is being installed and foam forms assembled.

stone is being packed down to be ready for the west approach form supports.

22 July:

the new railway underpass is complete except for paving

formwork supports for the west approach arc are being installed; one of the lighting standards

for the path is at the right

28 July:

work continues on the west approach formwork; it's low priority compared to the tower

work starts on the north tower rebar

4 August:

the formwork pillar support base is installed; the yellow pole is used to ensure the

form follows the desired arc

rebar is now complete on the south side of the tower base, including the massive reinforcement

around the stress-concentrating O-hole

precise positioning of the rebar forming the girdle around the O-hole is critical for tower

strength; some of the complex constraining bars and ties are visible here, as are some of the

brackets that will hold the O-hole lighting. The grey connecting rod is one of many that will hold

the inside and outside faces of the form together; each needs to withstand up to 50 t

tension during pouring due to the high fluidity of the concrete used

11 August:

the floor formwork for the west approach is complete and side rebar installation is starting

the Genivar design requires three types of specialized rebar for this section; from left to

right epoxy-coated iron, stainless steel, glass fiber-reinforced polymer

the north tower rebar is almost complete and outer face formwork is being assembled

22 August:

side rebar is almost complete for the west approach

tower outer face formwork is being assembled

1 September:

work continues on the inside tower formwork; no outer face has been installed yet

5 September:

inspections complete, outer face formwork is being installed on the south side

11 September:

a large storm drain under Highway 174 near Orleans collapses without warning, blocking a

major traffic artery. Bray puts all its resources into rebuilding the drain and re-opening

the highway as quickly as possible. Emergency crews work 24 hours a day, seven days a week to

remove the collapsed metal culvert and instal a concrete replacement. 14 days after the car-sized

sink hole was first reported, the road is paved and the highway is in full service for commuters.

The original cost estimate to reline the culvert was $1.5 million; the emergency replacement cost

$4.9 million

outer face formwork, almost complete on the north side, will await opening of Hwy 174

24 September:

landscaping, by MacDonell's Landscaping of Cornwall, starts at the west end

27-28 September:

the tower concrete is poured overnight to enable a continuous line of cement trucks to be used

with minimal impact on Airport Parkway traffic. No one was notified in advance and no photos have

ever been made available of this pouring. I was told quietly through the fence the next day that

an SCC concrete testing expert was onsite throughout the pouring, that this time every truckload

was tested individually (as I was taught to do at McGill in the early 1960s), that progress tests

were done throughout the pour of the critical sections around the O-hole, and that test cylinders

were cast for lab analysis to compare with the mockup tests

3 October:

the deck of the west approach arc is poured

formwork for the west railings is being cleaned up

4 October:

tie bars are being removed from the tower by old-fashioned muscle and hammer power

5 October:

face forms are being removed from the north side

Joe Wheeler and other engineers anxiously check the surface finish and integrity - looks good

Success! Outer face formwork is off and everything looks go for the next phase. Bray personnel

celebrate with a flag and hamburgers

12 October:

under the first sleet of the season, concrete pads are being prepared to support the scaffolding

for the upper half of the tower

23 October:

the lower tower is free of all formwork; scaffolding is being erected to build the top tower

the west approach deck is still supported by formwork while it cures; formwork for the side

beams is almost complete

25 October:

Ottawa Sun:

Airport

Parkway Bridge back on track

8 November:

scaffolding is taking shape to support the raised platform from which the top section of the tower

will be built; some of the top-tower formwork is being worked on in the foreground. Built-in scaffold

ladders are coated in yellow; two 40 m cranes are in use

17 November:

the platform, 15 m up, is complete with storage shack, toilet and stairs; the rear form

support for the top half of the tower is in place

26 November:

30 m up, side form braces are being added with the help of one of Bray's new

cherrypickers (blue) - it can reach 135' height and 70' sideways from its base

29 November:

installation of the 15 m long vertical rebar for the top tower section begins. The top

section of the tower is thick enough that regular iron can be used; it is being bent to the curve of

the tower on site. Some of the rebar constraining loops can be seen on the platform

5 December:

foundations are being prepared for the deck formwork over the parkway as a flagman stands by;

earth that will cover a styrene-cored slope up to the wall can be seen behind

the east ramp is almost complete except for landscaping; formwork with brackets that will support

working platforms for pouring the top tower is in front

13 December:

work continues on the rebar for the top half of the tower; the stairwell is wrapped in plastic

to reduce the wind chill during the climb; the wood latticework will support a plastic shroud to

enclose the entire section and allow it to be heated while the concrete sets

styrofoam is being laid around the west pier so the bridge will appear to rise out of the earth

18 December:

top section rebar complete, the front form face is being installed in drizzling sleet.

28 December:

the access door from the pathway into the South Keys bus terminal has been completed; it's

entirely glass both to light the hallway and to maximize visual openness of the pathway approach