|

Impact Crackers

780 000 ago, people were cracking nuts with stones (N.Goren-Inbar et.al,

Proc.Natl.Acad.Sci.USA, 99(4), 2455-2460, 2002). Chimpanzees may have been doing it even earlier.

We still can. Find a rock with a slight cup shape to it, and a boulder with a similar surface, and

the pieces stay together well.

| |

|

|

The technique can be improved by surrounding the nut with a belt. The belt limits the depth to which

crushing takes place, so it's easier to get large meat pieces. It seems more modern to use a steel

mallet, and may help protect fingers a bit, but a stone works just as well.

| |

|

|

Screw crackers

A more precise method is a machinist's vise. This gives perfect control, as a good vise is so rigid

that the shell is cracked precisely as much as you wish. Taking your time allows a significant

fraction of half-kernels.

| |

|

|

A screw was the principle of many kitchen nut crackers made a century ago, when most people

collected and cracked their own nuts. This cast iron one was made by the Perfection Nut Cracker

Company from 1914 and offers a massive 200x lever advantage.

| |

|

|

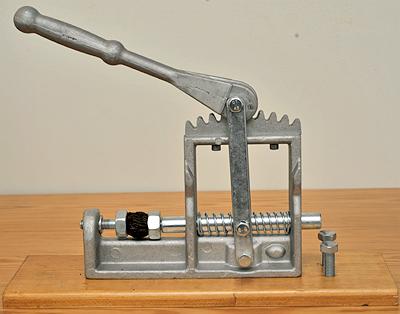

This light weight forged aluminum cracker has a lever advantage of 50x; it was made by Teague during the 1950's and offers the option of table-edge mount or bench mount. Its maximum opening of 85mm is larger than any nut I've ever seen

| |

|

|

Despite the appearance, this cast iron cracker is new. Made in China, it also comes in bright baked

enamel colours. However, it's inefficient to use - the wells in the anvils are so deep that many

turns of the screw are needed between the opening that permits the nut to be inserted and that

which cracks the nut. Also, the vertical space available for the nut is much smaller than the

thread, so some large nuts don't fit in. The arch is held on by screws, so the unit could be taken

apart and the excessive edges filed down, but I haven't bothered to do it.

| |

|

|

Lever crackers

Just about every American with a garage seems to have produced, and patented, a black walnut lever

cracker after breaking the first one they tried! Most are based on massive size and a huge lever advantage. Bernard

Contré makes this inexpensive (and unpatented) double-lever cracker that allows anyone to crack

the toughest nuts with its lever advantage of 40x.

| |

|

|

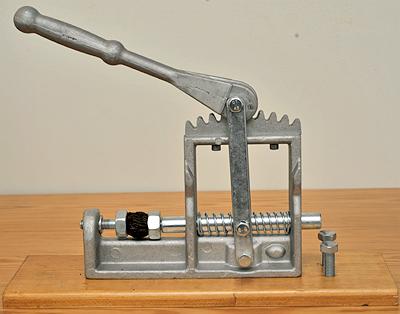

Some are more elaborate than others. This one is made for Duke; again, there are many similar designs

for sale, one by the Grimo Nut Nursery. Most seem conceived to

provide as many chances to pinch fingers as possible. But, Duke's has an added feature - a cast stop

in the frame that prevents half of the gear range being used until it is filed off by the user! Once

that is done, however, it works well, with a lever advantage of 60x.

| |

|

|

Amazon paid for Good Housekeeping Institute approval for this cracker. It's solid, grips nuts well,

and its lever ratio of 13 handles black walnuts with reasonable force. However, it has a curious

design limitation: there's an internal stop that prevents the lever going any lower than shown, so

it usually takes two presses to crack most nuts.

| |

|

|

The lever advantage of this cracker is 18, and it looks strong enough for black walnuts

| |

|

|

This old cast iron cracker by Sargent has a lever advantage of 22; the jaws don't close, instead the left hand jaw just rotates with the lever; it's strong enough for any nut

| |

|

|

Ratchet crackers

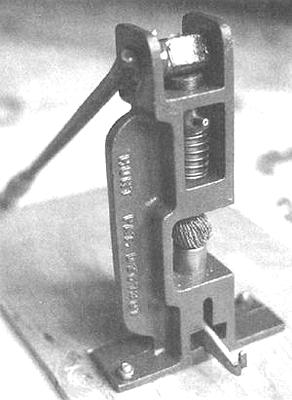

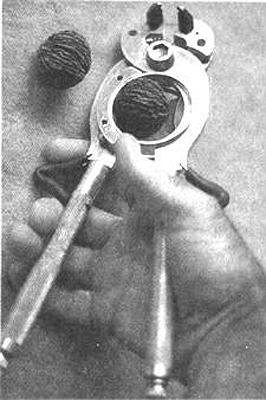

This cracker, made by C.L.Rimes in England in 1977, uses a lever ratchet system that quickly adjusts

to any size of nut. The top anvil is a sharp steel wedge that splits black walnuts with surprising

ease, especially if the wedge is placed on the seam; the lever advantage of 15x is sufficient that

cracking is controlled well.

| |

|

|

Cam crackers

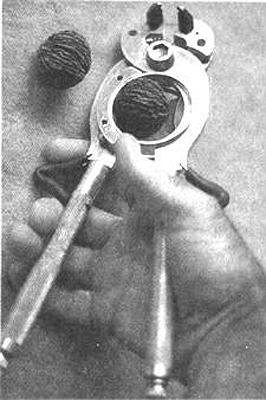

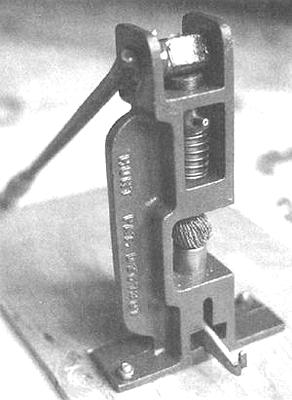

This massive cast iron vertical cracker was made (and patented of course) by Lawrence Hunt in 1982.

It uses a wedge to adjust an anvil to the position required by the nut being cracked.

It, and several similar designs, are still sold. One is sold in Canada by

Grimo Nut Nursery.

| |

|

|

Cutting crackers

The easiest small scale way to open black walnuts is by splitting or cutting them. My grandfather

Wallace did it with stump and axe, but with the skill of a lifetime splitting wood for a stove. I also

use an axe, but not having my grandfather's skill, place its edge on the suture and smack the axe with

a wooden mallet.

| |

|

|

A cracker that slices black walnuts in half was designed and patented by one

Gaston Fornes. It can't have been very successful,

I've never located one for sale.

| |

|