Damper

rod forks are cheap to make, and prevent the SV650 from competing with

the pricier Suzuki 600cc sport bikes equipped with cartridge forks.With fixed orifices in a damper rod, compression

damping force is

proportional to the square of bump velocity, and can deliver punishing

jolts to the rider hands and arms on sharper bumps. The idea is to

enlarge the existing damper rod holes so they no longer affect

compression damping, which is then taken over by the cartridge

emulators.

Emulators use a spring-loaded blow off valve to reduce harshness by

making compression damping roughly proportional to bump velocity.

To add emulators, you need to get the front end off the

ground. With

the bike still safely on the side stand, I loosened all the bolts

holding the front end together and lifted the rear with a paddock

stand. With a couple of car tires on the seats to keep the back down, a

hydraulic jack under the engine raises the front end nicely. Brake

calipers removed and supported by bungee cords, allowing wheel removal.

Once the wheel is off, you can stick a 31" long 2"x4" brace from the floor

up to the frame behind the triple clamp, anchored by a couple of cinder

blocks to act as a safety if anything goes wrong with the jack.

Damper

rod forks are cheap to make, and prevent the SV650 from competing with

the pricier Suzuki 600cc sport bikes equipped with cartridge forks.With fixed orifices in a damper rod, compression

damping force is

proportional to the square of bump velocity, and can deliver punishing

jolts to the rider hands and arms on sharper bumps. The idea is to

enlarge the existing damper rod holes so they no longer affect

compression damping, which is then taken over by the cartridge

emulators.

Emulators use a spring-loaded blow off valve to reduce harshness by

making compression damping roughly proportional to bump velocity.

To add emulators, you need to get the front end off the

ground. With

the bike still safely on the side stand, I loosened all the bolts

holding the front end together and lifted the rear with a paddock

stand. With a couple of car tires on the seats to keep the back down, a

hydraulic jack under the engine raises the front end nicely. Brake

calipers removed and supported by bungee cords, allowing wheel removal.

Once the wheel is off, you can stick a 31" long 2"x4" brace from the floor

up to the frame behind the triple clamp, anchored by a couple of cinder

blocks to act as a safety if anything goes wrong with the jack.

Undid the pinch bolts, removed the forks. Turned the preload adjustors

all the way in to put as much spring force as possible on the damper

rods. Using a length of 6mm allen key, 1/4" drive 6mm socket and

ratchet, loosened the bottom bolts. Set preload to minimum. Then

removed the fork top cap, drained oil and removed spacer, washer and

spring. While putting tension on the upper tube against the rebound

spring to keep the damper rod from turning, removed the bottom bolt,

then the damper rod and rebound spring.

Drilled the 4 existing 5/16" damper rod holes to 3/8" then 7/16",

doubling the effective area. Drilling through the curved damper rod

surface is tricky, the drill bit often sticks and stalls. A drill press

would have been handy. Left the rebound hole unchanged.

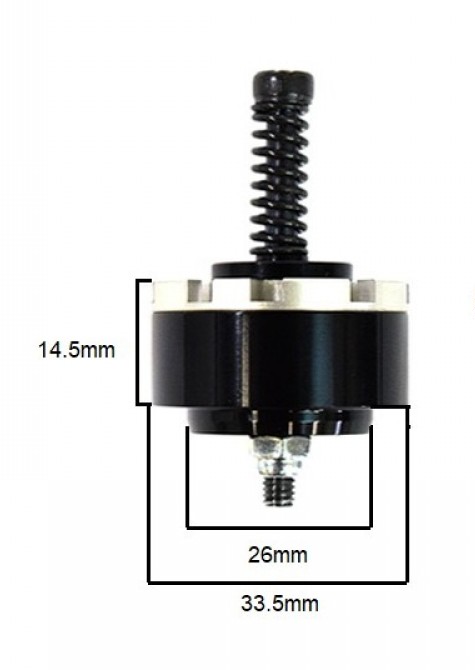

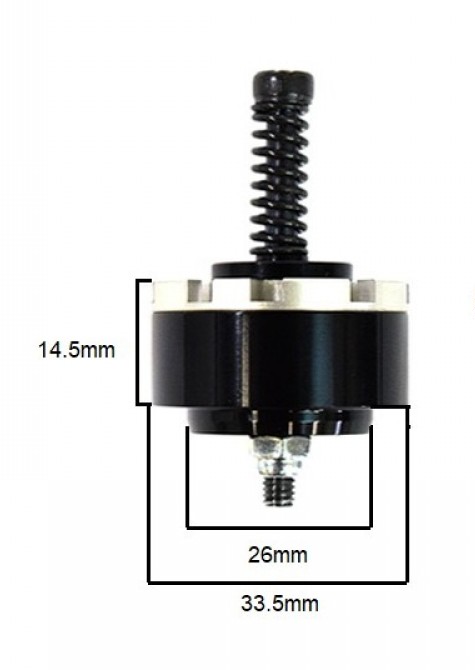

Set up the fork valves with 1 turn of preload, looking for a plush

ride. Bent a hook into the end of a coat hanger to snag the emulator

spring and lift out if required for adjustment. The fork valve height

is 14.5mm. By filing a groove in the very thin wall stock spacer, I cut the

existing 50mm length to 37.5mm, so 12.5mm shorter.

Set up the fork valves with 1 turn of preload, looking for a plush

ride. Bent a hook into the end of a coat hanger to snag the emulator

spring and lift out if required for adjustment. The fork valve height

is 14.5mm. By filing a groove in the very thin wall stock spacer, I cut the

existing 50mm length to 37.5mm, so 12.5mm shorter.

Installed rebound springs and the modified damper rods. Maximum travel measured as 120mm. The square end

of a 1/2" drive socket extension jammed lightly into the damper rod can

be used to prevent rotation when tightening the bottom bolt. I used 3

extensions together, 12", 5" and 4" x 3/8" plus adapter.

Installed the fork valves. With the forks compressed, added 10W oil up

to the 125mm mark. Installed springs, washers, spacers and fork caps.

It pays to mark the cap and the tube (masking tape) where the thread

engages.

Inserted forks back into the triple clamps and handlebars, tightened

lots of pinch bolts. Removed 2"x4" brace, installed wheel, speedo

sensor and brakes, then released the hydraulic jack. Torqued axle, brakes,

etc. Installed front fender.

With the preload adjustor set to 2 lines:

Unladen sag = 12mm

Laden sag = 35mm

Feb. 2021 Winter project. Ready for the 2021 riding season.

Damper

rod forks are cheap to make, and prevent the SV650 from competing with

the pricier Suzuki 600cc sport bikes equipped with cartridge forks.With fixed orifices in a damper rod, compression

damping force is

proportional to the square of bump velocity, and can deliver punishing

jolts to the rider hands and arms on sharper bumps. The idea is to

enlarge the existing damper rod holes so they no longer affect

compression damping, which is then taken over by the cartridge

emulators.

Emulators use a spring-loaded blow off valve to reduce harshness by

making compression damping roughly proportional to bump velocity.

Damper

rod forks are cheap to make, and prevent the SV650 from competing with

the pricier Suzuki 600cc sport bikes equipped with cartridge forks.With fixed orifices in a damper rod, compression

damping force is

proportional to the square of bump velocity, and can deliver punishing

jolts to the rider hands and arms on sharper bumps. The idea is to

enlarge the existing damper rod holes so they no longer affect

compression damping, which is then taken over by the cartridge

emulators.

Emulators use a spring-loaded blow off valve to reduce harshness by

making compression damping roughly proportional to bump velocity.

Set up the fork valves with 1 turn of preload, looking for a plush

ride. Bent a hook into the end of a coat hanger to snag the emulator

spring and lift out if required for adjustment. The fork valve height

is 14.5mm. By filing a groove in the very thin wall stock spacer, I cut the

existing 50mm length to 37.5mm, so 12.5mm shorter.

Set up the fork valves with 1 turn of preload, looking for a plush

ride. Bent a hook into the end of a coat hanger to snag the emulator

spring and lift out if required for adjustment. The fork valve height

is 14.5mm. By filing a groove in the very thin wall stock spacer, I cut the

existing 50mm length to 37.5mm, so 12.5mm shorter.