|

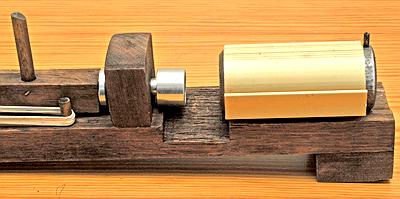

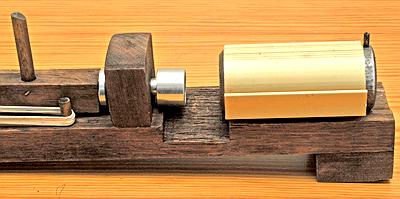

Impact crackers

This cracker has a wood hammer powered by a rubber band. The nut is placed between the anvils, the

hammer pulled back then released. Two or three tries cracks a pecan; no amount of trying comes close

to cracking a black walnut. The striker only moves a short distance, too little to crack many nuts.

The brass cover that slides over the nut is unnecessary; no pieces will fly from this cracker. The

anvil is a freely sliding 750 g weight - watch out not to let it slide off and drop on anything.

Both of the yellow aluminum pieces are extrusions obviously designed for other purposes, probably for

windows. The maker didn't bother to square the bottom foot so it sits flat, and the anvils don't

line up. It earned 3 patents for originality, but gets none from me for usefulness.

| |

|

|

Lots of decorative nut bowls plus hammer are sold; as with most, the 'hammer' is inadequate for any

but the easiest nuts. One, sized specifically for pecans, is sold as "The Wisecracker".

| |

|

|

Screw crackers

This is a common ornamental screw cracker from a century ago. The outside has the shape of half a nut,

and was often decorated like the shell of an English walnut, the kind found in most stores. Although

the screw is steel, the body is a soft zinc-like metal; it wouldn't last long cracking black walnuts.

| |

|

|

This cracker might win design competitions, but it fails at cracking many nuts. The top has to be

unscrewed a long way to insert the nut, then screwed back down to begin cracking. With force applied

sufficient to crack any but the easiest nuts, the screw pops up out of the threads. (Note to the

designer: the outside thread needs to wrap another 5 mm or so around the inside thread.)

| |

<

< |

|

Lever crackers - vertical

This table top model, made for Duke Co. in China with a lever advantage of 17x, should be able to

handle black walnuts. However its pivots are too weak and loose for them.

| |

|

|

This cracker has a lever advantage of 7.5x to raise the bottom of the mouth

to crack a nut. But, that's not enough for black walnuts, and its cast aluminum probably couldn't

take the stress either. And, it can't crack hazels or smaller nuts because its mouth is hollow.

| |

|

|

This cast iron cracker, made in China, comes with a wide assortment of figures on the top and a

variety of paint colours. The lever advantage is small but enough vertical pressure can be

applied to the broad handle to crack any nut. It fails with black walnuts because it gives

insufficient control to avoid shattering the kernels.

| |

|

|

This modern cracker is solidly made and can crack most large nuts other than black walnuts.

However, the high arch on the breaker makes it unable to crack even moderately small nuts such as

hazels. The ribbed recess is supposed to contain all the shell pieces, but many usually escape it.

| |

|

|

This enamelled Passover cracker is typical of many ritual crackers that fail at cracking hard nuts

because the end of the handle is beyond the support of the base and the connection between base and

top is weak. Of course, they are only intended for ceremonial use.

| |

|

|

Lever crackers - hand

This cracker, cast by Yongkang Hongan Hardware Tools Factory in China, is one of the

few single-lever crackers that can crack black walnuts without breaking. Its power comes from the

points on the inside that apply highly concentrated pressure on the shell. You need stronger hands

than most to crack black walnuts with it, and there are several similar models on the market that

break with black walnuts, so I put it here. It requires a special technique to get half kernels:

close the cracker, drop in the nut, open it just enough for the nut to drop down a bit, then

squeeze. If the nut doesn't crack the first time, allow the nut to drop down a bit further and try

again. If you simply drop the nut into the fully open cracker, once the shell begins to give way

the hand pressure required ends up shattering the kernels.

| |

|

|

This modern double-lever cracker is poorly designed: the steel jaws are strong but the plastic parts

are so weak they bend out of shape long before any hard nut gives way.

| |

|

|

This old double-lever iron cracker is an interesting design, however the pivots are too weak

for black walnuts.

| |

|

|

This is a quick-adjust cracker: press the top jaw into contact with the nut, then squeeze; the fine

teeth then engage to force the jaws closer together. It's lever ratio of 5.6x is inadequate for

black walnuts.

| |

|

|

This silver plated brass and steel cracker was typical of those used with silver tea sets a century

ago. My mother cracked many California walnuts with it, but it's not strong enough for any hard nut.

| |

|

|

Female legs are a common theme in decorative nutcrackers. Some are full-body nudes, others are

caricatures of female politicians. (Men are corkscrews.)

| |

|

|

Roosters are a common Asian theme for decorative nut crackers. The mouth of this one can be used for

tiny nuts such as beech or beaked hazel.

| |

|

|

This two-sided cracker is a common design - small nuts are cracked with the arms as shown, larger

ones with the arms reversed. This one has the neat feature that the ends of the arms can help to

extract the kernels from the shell after cracking.

| |

|

|

This steel cracker keeps its crackers for both sizes of nuts close to the pivot, making the cracking

of large nuts easier than with one-sided designs that put the large cracker farther away.

| |

|

|

This cast aluminum cracker from Russia is strong enough for any nut hand pressure can crack, but

few have hands strong enough to use it with black walnuts.

| |

|

|

This finely made little Turkish brass cracker is designed specifically for pistachios.

| |

|

|

This brass squirrel cracker can handle easy nuts, but will bend or break with hard ones.

| |

|

|

This brass alligator cracker is too weak for most nuts; many I've seen have been bent out of shape.

| |

|

|

This squirrel cracker is not only too weak for most nuts, the gap in the squirrel's mouth

is too large for many hazelnuts.

| |

|

|

This decorative cracker is almost useless at cracking nuts, as it offers no lever advantage at all;

it has to be pounded with a fist and usually shatters the kernels. The gap between its teeth is too

large for any nut smaller than a pecan.

| |

|

|

This is a unique lever system: it's held vertically with the rods square, then a nut dropped through

the hole comes to rest firmly held between the rods. A twist to left then right cracks the nut. The

rods of this one are of micarta, which limits its strength; if made of steel the design could crack

any nut that would fit inside.

| |

|

|

Ratchet crackers

Proudly marked Patented May 13, 1913, this cracker could probably handle black walnuts if it worked,

but it's far too poorly made and fitted for practical use. Moving the handle to the left, the

assembly can move freely to contact the nut; swinging the lever over to the right is then supposed

to allow a ratchet tooth to engage then crack the nut. It jams easily, the tooth has to be guided

into the ratchet, then the mechanism doesn't move far enough to crack most nuts.

| |

|

|

Cam crackers

Cam mechanisms require a spring to hold the cracking lever tight to the cam - this cracker fits it

into the left support. It works opposite to the usual way - the handle is lifted to the left to

crack the nut.

| |

|

|

This plastic conical design uses an internal cam to move the cracking lever; the connection of the

cracking lever incorporates the spring. It's a neat design, needing only three pieces that latch

together, and gives good control of cracking with its 7x lever advantage. However, I'm certain

it would break with black walnuts.

| |

|

|

This French cracker uses the inside of a handle as a cam to produce a double-lever action. It's

strong enough for black walnuts, but the lever advantage of 4.3 is too low for hand cracking.

| |

|

|

Cutting crackers

This model by Duke is supposed to cut the side of the nut shell off and catch the shell bits in

the curved piece. It's not very well made, only works on a small size range of nuts, and can't

even make a scratch on black walnuts.

| |

|

|

Wooden crackers

This finely carved hardwood cracker is probably from India. The thin wood pivot axle makes

it suspect for anything but decorative display.

| |

|

|

Carvings of figures are a common theme in decorative wood nutcrackers. However, besides

having a weak pivot axle, this one can't open wide enough even for a hazelnut as supplied.

| |

|

|

This good looking little cracker is stronger than most other wood ones I've seen. The wood

grain is in line with the screw (unlike ones with a side screw that split when the screw is

tightened). But, I'll still not risk it on a black walnut.

| |

|

|

This unique cracker works on a cam principle: turn the top to squeeze the nut until it

cracks. It will only work well with smooth nuts, but should handle pecans. We don't have

one in the ECSONG collection because it's sold as a design masterpiece, far too expensive

to be worth it.

| |

|

|

Soldiers, along with baseball players, are popular nutcracker figures. Unlike many,

this 35 cm high one is strong enough that it can actually crack some nuts.

| |

|

|

This is a traditional design of nut bowl plus cracker. The screw on this one is so weak

I doubt it could handle even a pecan.

| |

|

|

This is another traditional design of nut container plus cracker. The lever is strong

enough for most nuts.

| |

|

|

Non-cracker Nut-related

This finely-made Chinese system is designed to remove nut meats after cracking. The instructions

are on the tiny package. I've not been able to find anything to translate them; if you can, please

contact me.

| |

|

|

This isn't designed to shell nuts, it's made to cut betel nut kernels into pieces for

chewing. Betel nuts contain alkaloids and have been chewed along with betel leaves since

antiquity for a variety of claimed medicinal effects.

| |

|

|

Although this can crack nuts, it has a place in my kitchen as the best garlic press I know -

the projections on the piston match those in the body so all the garlic is pressed.

| |

|

<

<