September 2011 coming home from a long trip, a multi-day cool spell

(5.5 deg.

C) had numb fingers despite thinsulate gauntlets. This got me thinking

about grip heaters. I've never much liked the kind that go under or

over the grips, particularly that the wiring rotates with the throttle

and gets in the way of the throttle lock.

Ordered some bits and pieces from eBay to fabricate grip heaters

internal

to our hollow bars. The Concours bars are aluminum, so they

conduct heat nicely. I thought this idea was original, but it seems

the concept is already established for motorcycles and

snowmobiles (Symtec

Heat Demons, Polly).

Ordered some bits and pieces from eBay to fabricate grip heaters

internal

to our hollow bars. The Concours bars are aluminum, so they

conduct heat nicely. I thought this idea was original, but it seems

the concept is already established for motorcycles and

snowmobiles (Symtec

Heat Demons, Polly).

Components:

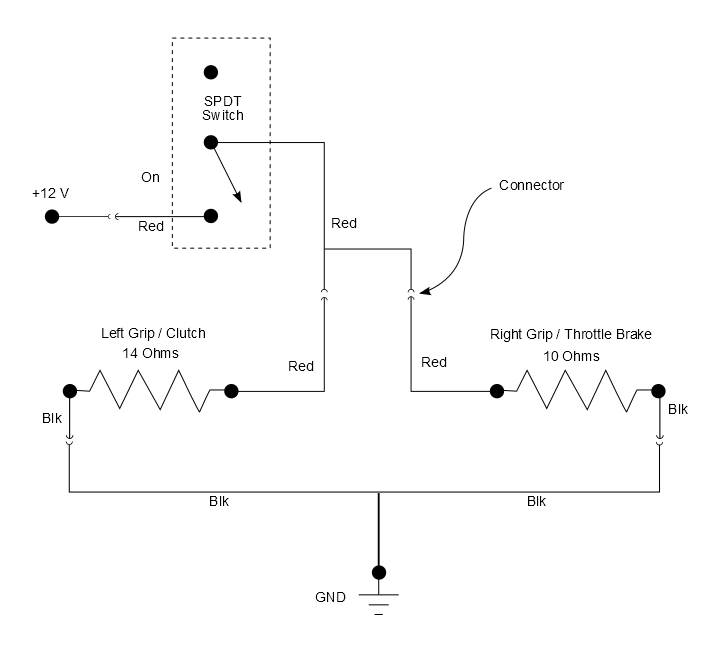

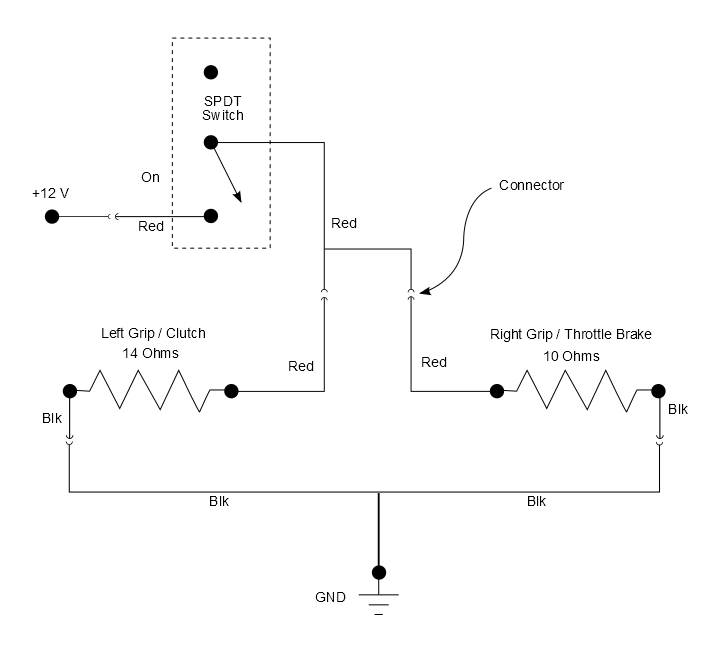

- Miniature SPDT switch (tried DPDT first).

- Waterproof switch cap.

Solid bare copper wire #20 GA

Solid bare copper wire #20 GA- High-temp fiberglass insulating sleeving

- Stranded #18 GA wire

- Heat shrink tubing

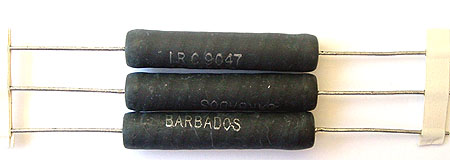

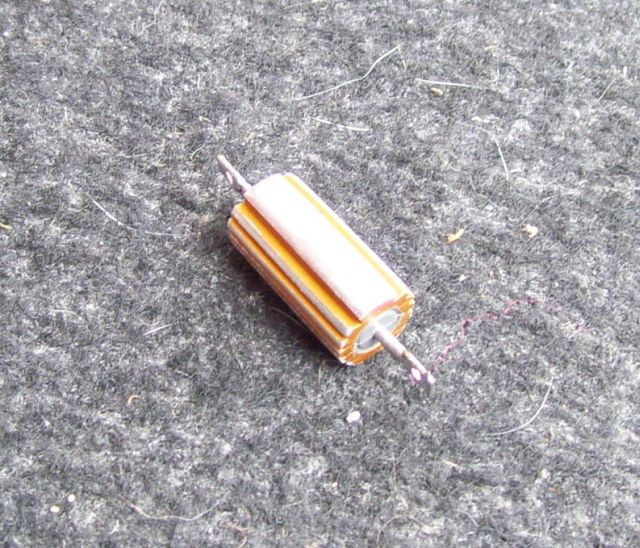

- Aluminum-clad Resistors (tried axial first)

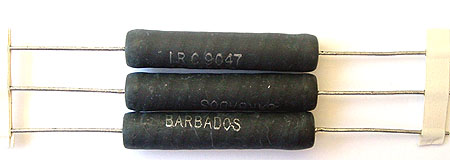

Prototype 1

The first bench setup consisted of a couple of 7.5 ohm 10W tubular

axial lead resistors in series in a spare left handlebar, dissipating a

total of

roughtly 14W from a battery conected to a charger. The resistors had an

air

gap of maybe 1/8" to the inside of the bar, so by both conduction and

convection, heat could escape in any direction, including sideways then

out thru the switch or the bar end. The resistors got hot but not much

came out through the grips.

The heat all has to get out to the atmosphere somehow, and I intially

thought that only the power level was significant while internal

physical configuration didn't matter. But getting the heat to go where

you want is the trick, with as little as possible elsewhere.

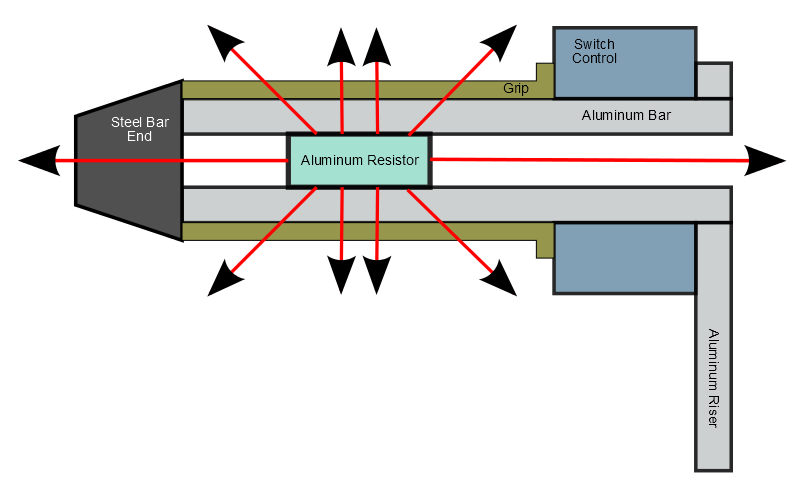

Ideally the heat should flow directly outward from the resistor, thru

the bar grip and glove and into the hand.

Prototype 2

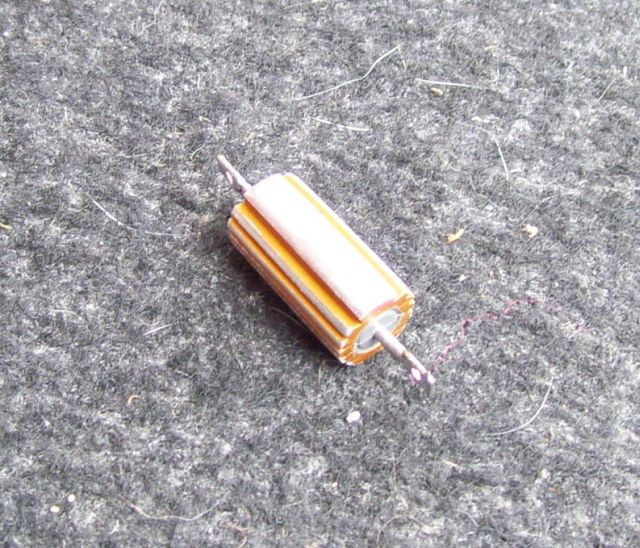

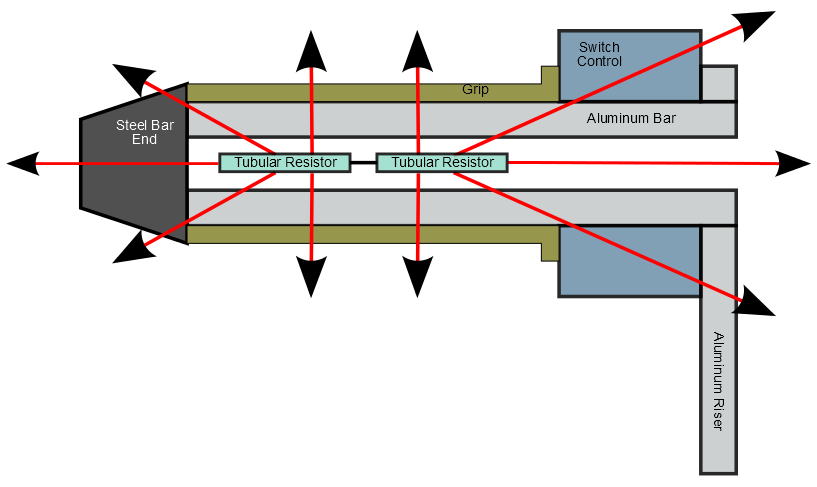

Aluminum has a much better thermal conductivity than air. So

I bought some 25W aluminum-clad resistors and filed them to just

slide/fit inside the bar, with an extra longitudinal groove to pass the

insulated return wire. It helps to file the rough edges off the

inside-bar tube weld to ease insertion.

Aluminum has a much better thermal conductivity than air. So

I bought some 25W aluminum-clad resistors and filed them to just

slide/fit inside the bar, with an extra longitudinal groove to pass the

insulated return wire. It helps to file the rough edges off the

inside-bar tube weld to ease insertion.

The resistors make good thermal contact to the bar, reducing the air

gap to essentially zero and this yielded much better results. A single

resistor is also a more concentrated heat

source than 2 resistors in series.

Convection transfer is largely eliminated, except from the resistor

ends. For conduction, the thermal resistance directly outward thru the

aluminum sleeve, bar and grip is lower than any sideways path through

the air to

either the switch or the bar end. There's less sideways loss, so for

the same 14W of bench test power, more heat gets to the hand.

The aluminum resistor is rated at 25W. Nothing melted or shorted. One

little irony is that these resistors run cooler because

there's a better heat path to atmosphere.

Installed Version

The installed version uses ~10 ohms on the right/throttle side, giving

19.6W, 1.4A @ 14V nominal. The left side uses ~14 ohms giving 14W, 1A.

The additional power on the right is to compensate for higher sideways

heat losses due to the thermal resistance of the throttle tube and air

gap.

Installation

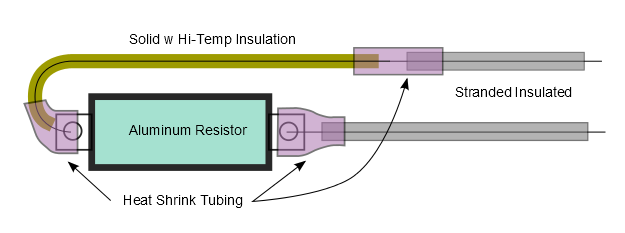

Mechanically, the tricky part is handling the return wire. It's in a

tight groove between the resistor and the bar, and has to be impervious

to high temperature. To prevent current flowing through (and ruining)

the steering head bearing, it cannot make electrical connection with

the bar.

Mechanically, the tricky part is handling the return wire. It's in a

tight groove between the resistor and the bar, and has to be impervious

to high temperature. To prevent current flowing through (and ruining)

the steering head bearing, it cannot make electrical connection with

the bar.

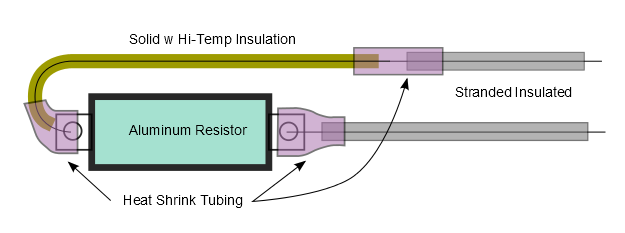

The return lead is a few inches of #20 GA solid bare copper wire,

inside a high-temperature (good to 600 deg. C) insulating

sleeve. At the far end, heat-shrink tubing covers the resistor

connection and the insulating sleeve. At the near end, an insulated

stranded wire is soldered to the solid return lead, with heat-shrink

over the sleeve, connection and insulation. The stranded connection to

the resistor is

also heat-shrunk, and the two leads are taped together for protection.

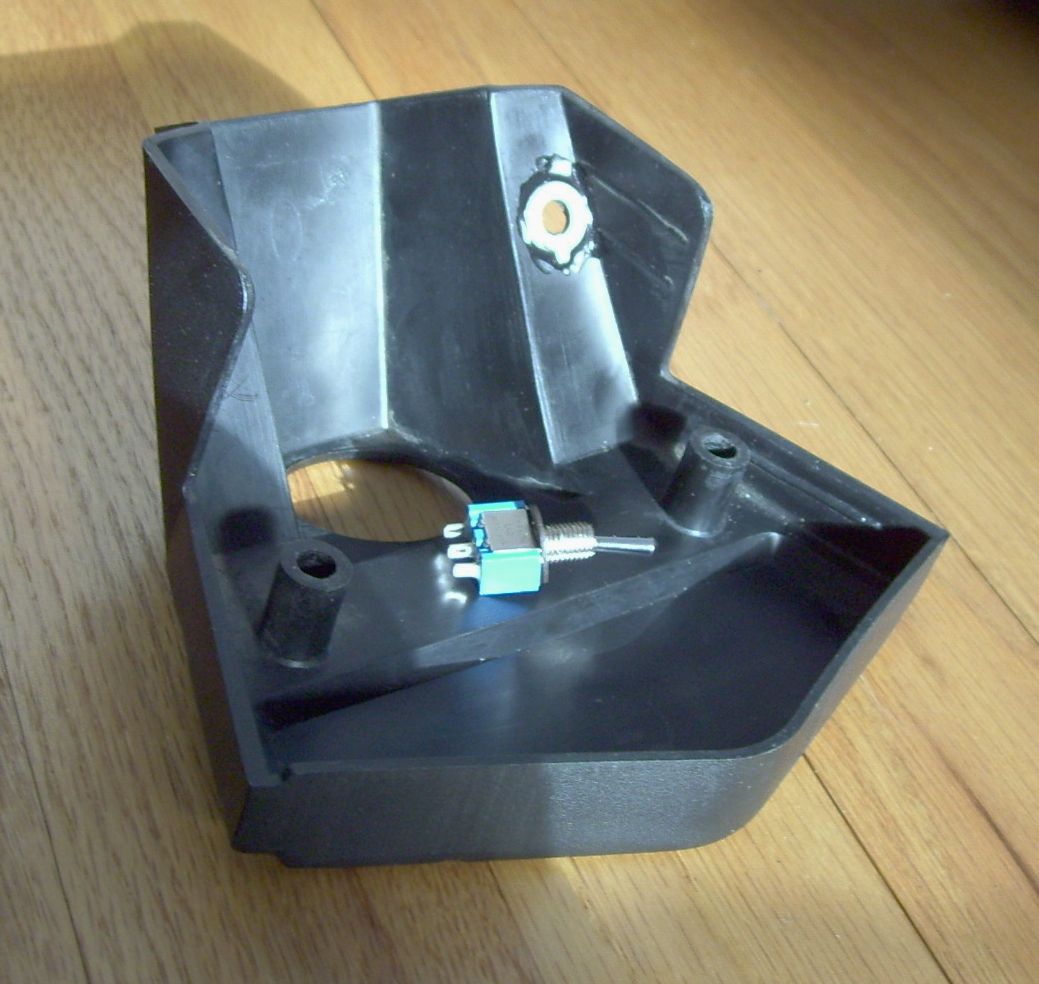

I decided to

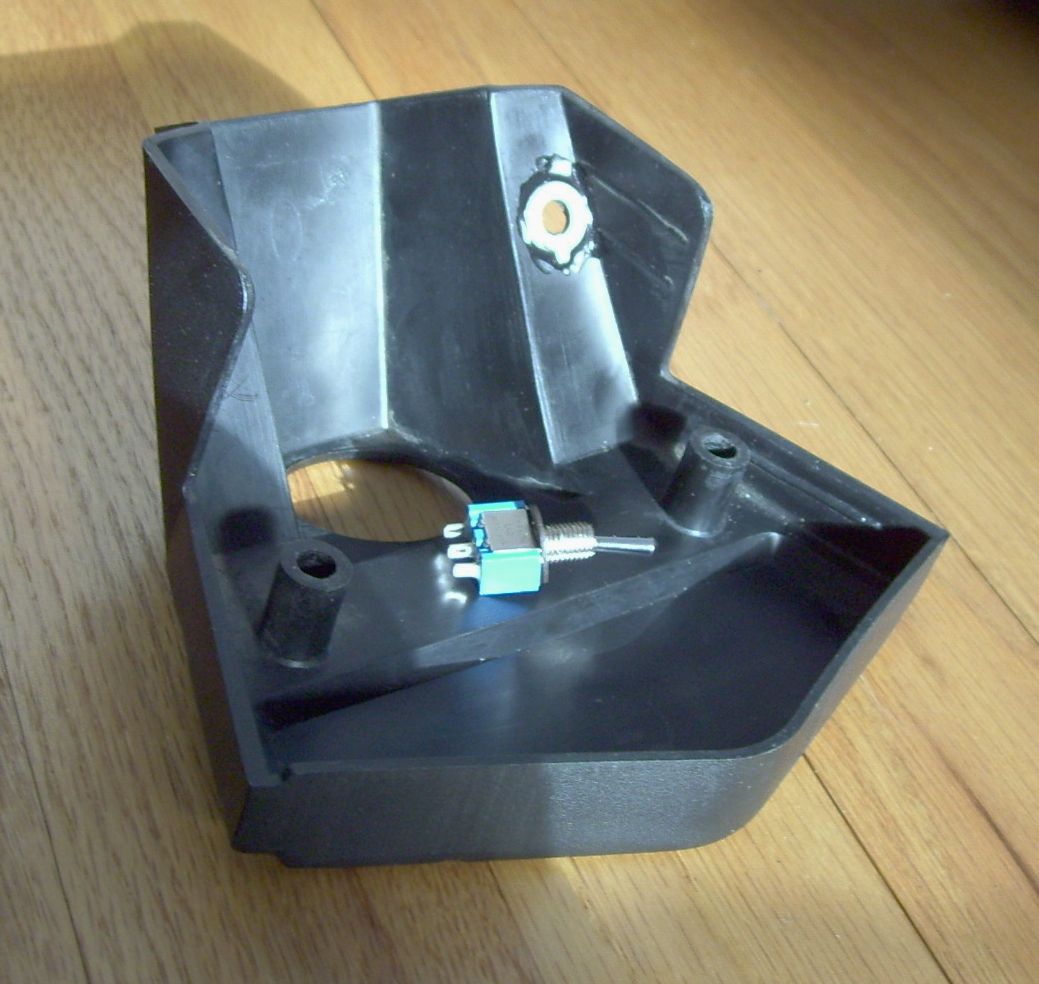

install the on-off switch in the ignition switch bezel to

allow actuation with the left hand while the right is on

the throttle. This minimizes the number of wires which

bend when the bars are turned, only the main 12V hot and ground

wires. The DPDT switch was just a smidge too big to fit there, so I

ordered a narrower SPDT switch.

I decided to

install the on-off switch in the ignition switch bezel to

allow actuation with the left hand while the right is on

the throttle. This minimizes the number of wires which

bend when the bars are turned, only the main 12V hot and ground

wires. The DPDT switch was just a smidge too big to fit there, so I

ordered a narrower SPDT switch.

Drilled a 1/4" hole in the ignition switch bezel about 1"

forward of the back edge. Epoxied the orientation washer that

came with the switch to the underside of the bezel. Used one more 1/4"

washer as a shim under the bezel to adjust the switch height

protruding above the bezel to match the waterproof switch cover height.

The cover threads onto the switch and directly down onto the bezel top.

Switched 12V is obtained from pin 8 of the J-Box. Routed

the 12V power source and ground wires under

Switched 12V is obtained from pin 8 of the J-Box. Routed

the 12V power source and ground wires under  the

tank, along the cable to the ignition switch, terminating in connectors

under the top triple clamp, left side. Wired the switch under the bezel

with a connector to the 12V source under the triple clamp and

connectors to deliver 12V to the heaters.

the

tank, along the cable to the ignition switch, terminating in connectors

under the top triple clamp, left side. Wired the switch under the bezel

with a connector to the 12V source under the triple clamp and

connectors to deliver 12V to the heaters.

Drilled 3/16" holes in the plastic inside bar caps for the heater

external

leads. A dab of RTV on the wires to keep water out. Stuffed a bit of

fiberglass into the bar at each end of the resistors to control

convection losses and keep the heat focused on the grip area.

Routed the heater wires immediately forward, then outwards under the

brake/clutch switch, down the outside of the bar risers, then under the

upper triple tree. Negative leads connect to ground wire connectors

under

the triple clamp, positive leads sneak up into the bezel connectors.

The right heater negative wire passes under the ignition guard bracket,

between the ignition switch and the top triple clamp to get to the

ground lead on the left side.

Results

The switch is small and the cover black, doesn't spoil the stock

look. Most of the wiring is hidden, you can just see the wire

poking out the inside bar ends.

The switch is small and the cover black, doesn't spoil the stock

look. Most of the wiring is hidden, you can just see the wire

poking out the inside bar ends.

For me, hand discomfort starts around 5 deg. C and below. Got things

ready in the cold garage over the winter for a test ride in

the spring. First ride of the season was a Mar. 27/2012 evening ride around

Ottawa at 3 deg. C., deliberately using normal (thin) riding

gloves rather than (thick) insulated gauntlets.

The heat effect is warmth rather than sizzling, just enough to

reduce the pain in the fingers. Because of the aluminum bar mass, the

heat takes a while to become noticeable. If it's cold enough for

heaters to be necessary, they can stay on all the time - no need

for a variable controller.

Nov. 2012 Update

Well, November was 'good' here in Ottawa in the sense that the roads

were dry and the temperatures hovered around +2 deg. C., so I had

plenty of chances to use the grip heaters. With 14W on the left and 20W

on the right, the left would warm up more quickly (more direct

heat path) and the right more slowly (trickling through both the

throttle tube and the grip). However, after a few miles, the right

became hotter than the left. Still not so hot that I had any urge to turn

off the power. And my hands decided that they preferred hotter to not so

hot.

So a modification is planned. I'm changing the left resistance to 10

ohms to give the same 20W power as the right. The resistor has been

ordered and received, installation planned for over the winter.

Fortunately, most of the work can be done in the warm basement instead

of the freezing garage.

Solid bare copper wire #20 GA

Solid bare copper wire #20 GA

Solid bare copper wire #20 GA

Solid bare copper wire #20 GA

Aluminum has a much better thermal conductivity than air. So

I bought some 25W aluminum-clad resistors and filed them to just

slide/fit inside the bar, with an extra longitudinal groove to pass the

insulated return wire. It helps to file the rough edges off the

inside-bar tube weld to ease insertion.

Aluminum has a much better thermal conductivity than air. So

I bought some 25W aluminum-clad resistors and filed them to just

slide/fit inside the bar, with an extra longitudinal groove to pass the

insulated return wire. It helps to file the rough edges off the

inside-bar tube weld to ease insertion.

Mechanically, the tricky part is handling the return wire. It's in a

tight groove between the resistor and the bar, and has to be impervious

to high temperature. To prevent current flowing through (and ruining)

the steering head bearing, it cannot make electrical connection with

the bar.

Mechanically, the tricky part is handling the return wire. It's in a

tight groove between the resistor and the bar, and has to be impervious

to high temperature. To prevent current flowing through (and ruining)

the steering head bearing, it cannot make electrical connection with

the bar.

I decided to

install the on-off switch in the ignition switch bezel to

allow actuation with the left hand while the right is on

the throttle. This minimizes the number of wires which

bend when the bars are turned, only the main 12V hot and ground

wires. The DPDT switch was just a smidge too big to fit there, so I

ordered a narrower SPDT switch.

I decided to

install the on-off switch in the ignition switch bezel to

allow actuation with the left hand while the right is on

the throttle. This minimizes the number of wires which

bend when the bars are turned, only the main 12V hot and ground

wires. The DPDT switch was just a smidge too big to fit there, so I

ordered a narrower SPDT switch. Switched 12V is obtained from pin 8 of the J-Box. Routed

the 12V power source and ground wires under

Switched 12V is obtained from pin 8 of the J-Box. Routed

the 12V power source and ground wires under  the

tank, along the cable to the ignition switch, terminating in connectors

under the top triple clamp, left side. Wired the switch under the bezel

with a connector to the 12V source under the triple clamp and

connectors to deliver 12V to the heaters.

the

tank, along the cable to the ignition switch, terminating in connectors

under the top triple clamp, left side. Wired the switch under the bezel

with a connector to the 12V source under the triple clamp and

connectors to deliver 12V to the heaters.  The switch is small and the cover black, doesn't spoil the stock

look. Most of the wiring is hidden, you can just see the wire

poking out the inside bar ends.

The switch is small and the cover black, doesn't spoil the stock

look. Most of the wiring is hidden, you can just see the wire

poking out the inside bar ends.