After 3 sets of LED dash light completely died, I did some head

scratching as to cause.

Each

T10 wedge bulb consists of an LED wired in series with a small,

current-limiting resistor. Initially, I thought vibration was the

culprit, but the resistor-LED connection was fine in all cases.

Each

T10 wedge bulb consists of an LED wired in series with a small,

current-limiting resistor. Initially, I thought vibration was the

culprit, but the resistor-LED connection was fine in all cases.

Next was the possibility of voltage spikes.

When

the starter disconnects, a voltage transient is generated ('back EMF')

and injected into the electrical system. If this is positive, a bit of

extra current would flow through the LEDs in the forward direction and

shouldn't do very much harm (i.e. low voltage x low current).

If

the transient is negative (i.e. driving the nominal +12V bus negative

with respect to ground) and large, it might exceed the reverse

breakdown voltage of the LEDs, causing high voltage x low current =

higher power and blowing the little suckers out.

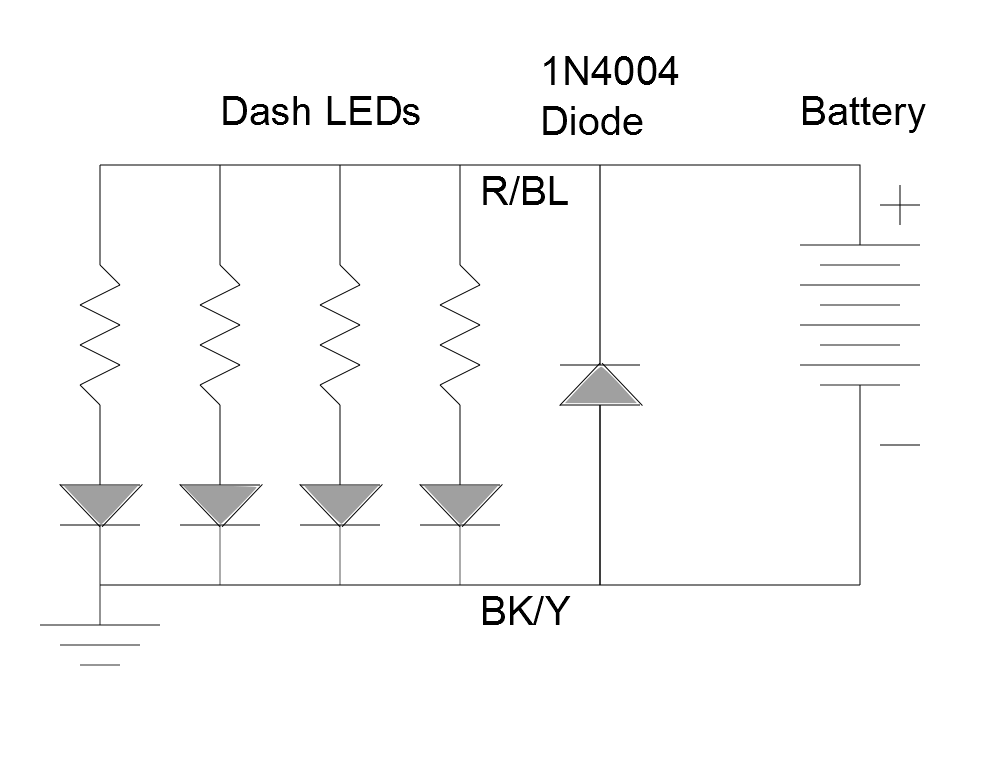

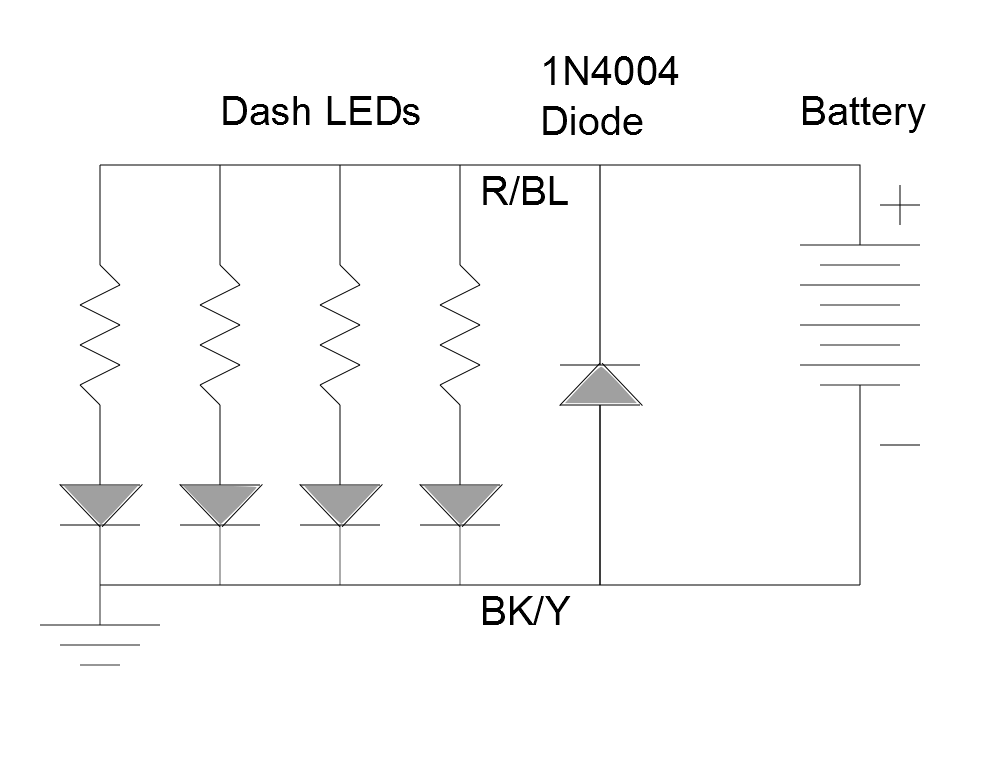

To check out

this theory, I bought a 4th set of dash LEDs and dug a 1N4004 diode out

of the electronic junk box. The idea is to wire the diode across the

dash light bus so that normally it's reverse biased and does not

conduct, but if/when there is a negative pulse, it conducts and

maintains the voltage below dash-LED-blowing levels. I scraped the

insulation off one blue/red LED wire and soldered the cathode (the end

with the white line) to it, and connected the anode under the

yellow/black screw terminal on the back of the meter module.

Best I can say for all this

is the LEDs are cheap on eBay and work well before they blow out.

Results to follow.

Best I can say for all this

is the LEDs are cheap on eBay and work well before they blow out.

Results to follow.

Oct. 2014 Results

Well,

2 of these lights have become intermittent despite the little diode. I

think the low-power dash lights are not up to the vibration level of

motorcycling. The higher power LEDs in the tail light and turn signals

seem fine. Going back to incandescent for the dash lights.

Trying Again - End November 2015.

Reasoning

that dash LED failures may be caused by vibration cracking the

connections, I decided to try my hand at circuit potting. The idea is

to make the circuit more mechanically rigid, so connections don't flex

and break.

Bought some more T10 4 SMD

LEDs (see above),

about $1.50 for 10 on eBay.

Bought some more T10 4 SMD

LEDs (see above),

about $1.50 for 10 on eBay.

Mixed

up some JBWeld on the bottom outside of a glass jar, and heated it up

in the microwave to thin it. Using a toothpick, I drizzled the epoxy

into the center and corner spaces of the mounting plate holding the

little SMD LEDs.

Installed and tested four of these in the cold

garage. So now the packaging looks a little ugly, but the light is not

impacted, and I'm hoping they last more than the typical 'work for one

season' of the past.

Best I can say for all this

is the LEDs are cheap on eBay and work well before they blow out.

Results to follow.

Best I can say for all this

is the LEDs are cheap on eBay and work well before they blow out.

Results to follow.