TECHNIQUES OF MOVIE FILM PROCESSING: A basic overview

by George Selinsky

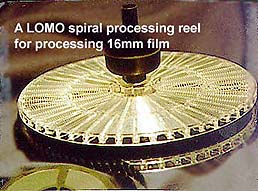

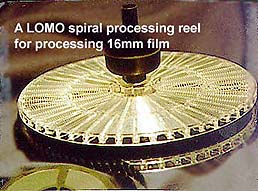

I Spiral Reel - the same way small rolls of 35mm still film are processed, spiral reels are metal or plastic reels that have a spiral groove on both flanges. When the film is loaded properly, these spiral beveled flanges preserve a continous space between the film that allows the film's emulsion to have contact with chemistry.

Pros:

Takes up very little space and requires a very minimal amount of chemicals. Efficient processing design, and use of chemistry. Portable. Gentle to the film. Some can handle several formats.

Cons:

Difficult to learn how to properly load. Mistakes can be easily made in loading, which can damage the film- damaged film will buckle and cause more problems. Difficult to load large amounts of film onto a large reel. Very hard to find. Cannot be homemade.

II Separator Strip - similar to the spiral reel, except instead of a spiral groove, the film is wound onto a reel together (in "bipack") with a special plastic strip of film that has grooves on the sides and holes in the middle. These grooves serve the same purpose as the grooves on the spiral reel - that is they allow the chemicals to have contact with the film emulsion by keeping the film separate from itself when wound onto a reel.

Pros:

Easy to thread. Relativley inexpensive. Gentle on film.

Cons:

Not a very uniform method of processing, a bit time consuming to thread properly. Very difficult to find. Drying is difficult. Difficult to make at home.

III Rack and Tank - a frame that has rollers on opposite sides. The film is wound around this frame in loops so that the emulsion faces outward and is exposed to the chemistry maximally. The rack is then steeped into a tank full of chemicals.

Pros:

A very uniform way to develop film. Certain designs permit large capacities of film to be processed at a time. Easy to agitate in chemistry. Some roller designs can be threaded easily with leader. Easy to dry. Can be homemade.

Cons:

Greater risk of scratches if rollers are not clean. Stresses film during processing. Difficult to find. Takes a lot of chemistry per foot of film. Development must take place in the dark with most designs.

IV Reel and Trough - the film is wrapped around a large rotating cylinder. This cylinder is partially steeped into a "trough" of chemicals, and rotated at a high enough speed to provide even coverage of all the film.

Pros:

Can be homemade. Permits easy use of one shot chemistry. Easy drying. Easy to thread.

Cons:

Chemicals oxidize very quickly, and as such can only be used once. Difficulty in tempurature control. Requires a lot of room. Greater stress on film. Process is not very uniform at all times. Development must take place in the dark with most designs. Film is more prone to dust.

V Rewind Tank - the film is shuttled between two spools back and forth, through a bath of chemistry.

Pros: Requires very little space. Uses very little chemistry. Inexpensive and can be homemade. Threading is the easiest. Accomodates all formats.

Cons: Very labor intensive. Extremely difficult to determine processing times due to fixed rates of emulsion exposure. Processing times are very long. A rather nonuniform and inconsistent way to develop film. Chemicals are quickly oxidized. Cannot be used for drying.

The Morse / Arkay G-3 processing tank, often sold on ebay for around $40 - can be purchased new from Arkay for $80. Some older models have a reexposure window, important for processing reversal films. These were used frequently by the US military during wartime.

VI Hose method - the film is threaded into a hose, and the chemistry is poured into the hose.

Pros: A hose can be gotten at any hardware store. Relativley format independent (width of hose dictates film size)

Cons: Couldn't even begin to speculate, although I imagine it's quite cumbersome.

VII Hand processing - the film is simply dumped into a bucket of chemicals and sloshed around by hand.

Pros: Takes extremely little intelligence to do. Provides extremely uneven development, and emulsion damage, which may be desireable for some purposes. It is considered to be a separate artistic technique by its adherents for this very reason. No dependency on format. Extremely inexpensive, equipment can be found everywhere.

Cons: What it provides in ease and inexpense, it completely lacks in quality. Not a way to develop film according "to spec", even a rewind tank will perform considerably better. Handling chemistry is toxic unless you wear gloves and perhaps eye protection when sloshing about. Can't be used for drying. Oxidizes chemicals quickly.

VIII Continuous or "mechanized" processors - the film is threaded through an elaborate system of rollers (mechanized racks) and passes through different tanks, where it comes into contact with different chemical baths. The film is then automatically transported into a drier cabinet, and then onto a reel. The method all commercial labs use to process movie film.

Pros: Very little labor required during processing, aside from monitoring solutions and drying - very automatic. Very even development. Solution times are shorter due to efficiency. Minimal solution oxidation is efficient and permits replenishment.

Cons: Extremely expensive equipment, very difficult to engineer properly. Requires constant cleaning and calibration. Solution is lost when leader is passed through baths, requiring additional replenishment. Takes up a lot of space. Stresses the film significantly, prone to scratches if not kept clean. Requires a lot of solution per foot of film, especially if the processor is particularly fast. Mistakes mid-process (such as tearing of film) is very difficult to correct, and can damage the whole batch.

Note: Also see Martin Baumgarten's more comprehensive posting from The 8mm Metadirectory